Precision Optical Cubes: Understanding, Utilizing, and Maintaining High-Performance Optical Components

Precision optical cubes are crucial components in various optical systems, where accuracy and performance are paramount. These optical elements are designed to manipulate light with exceptional precision, making them essential for applications in scientific research, telecommunications, imaging, and more. This comprehensive guide delves into the world of precision optical cubes, covering their types, functions, applications, and best practices for maintenance.

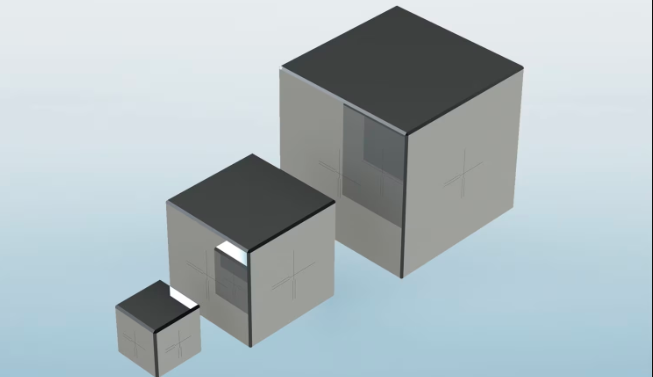

1. What Are Precision Optical Cubes?

Precision optical cubes are optical components engineered to handle light with a high degree of accuracy. They are typically made from high-quality optical glass or other advanced materials and are used in systems where precise light manipulation is critical.

1.1 Structure and Material

precision optical cubes are usually cubic in shape, allowing for the precise alignment and manipulation of light beams. The materials used, such as optical-grade glass or synthetic crystals, are chosen for their clarity, durability, and minimal optical distortion. The surfaces of these cubes are meticulously polished to ensure optimal performance.

1.2 Types of Precision Optical Cubes

Different types of precision optical cubes serve various functions, each designed to meet specific requirements:

- Beam Splitter Cubes: Designed to divide a light beam into two separate beams with high precision. They are essential in optical systems that require exact beam splitting.

- Dichroic Cubes: These cubes are coated to reflect certain wavelengths while allowing others to pass through, useful for isolating or combining different light wavelengths with high accuracy.

- Polarizing Cubes: Utilized to separate light into polarized and non-polarized components, crucial for experiments and devices requiring precise polarization control.

2. Applications of Precision Optical Cubes

Precision optical cubes are used in a wide range of applications where exact light control and manipulation are required.

2.1 Scientific Research

In scientific research, precision optical cubes are used in optical instruments and experiments where accurate light control is necessary. They are integral in spectrometry, microscopy, and laser systems, helping researchers achieve precise measurements and observations.

2.2 Telecommunications

In telecommunications, precision optical cubes are critical for fiber optic systems. They enable the precise splitting and combining of light signals, which is essential for high-speed data transmission and minimizing signal loss over long distances.

2.3 Imaging Systems

Precision optical cubes are employed in various imaging systems, including high-end cameras and microscopes. They help in directing and focusing light to enhance image clarity and accuracy, which is vital for detailed and precise imaging.

2.4 Optical Testing and Calibration

Precision optical cubes are used in optical testing and calibration to ensure that systems are performing to their specifications. They allow for precise adjustments and measurements in optical setups, ensuring accurate results.

3. How Precision Optical Cubes Work

The functionality of precision optical cubes is based on their ability to manipulate light with high accuracy, utilizing various optical principles.

3.1 Beam Splitting

Beam splitter cubes are coated with partial mirrors that divide incoming light into multiple beams. The precision of these coatings ensures that the light is split exactly according to the desired ratio, crucial for applications requiring accurate light division.

3.2 Wavelength Separation

Dichroic cubes use specialized coatings to reflect and transmit different wavelengths of light. This selective reflection and transmission are achieved with high precision, allowing for the separation or combination of specific light wavelengths in various optical applications.

3.3 Polarization Control

Polarizing cubes employ polarizing filters to split light into polarized and non-polarized components. The alignment and quality of these filters are critical for precise polarization control, which is essential in many optical experiments and devices.

4. Selecting the Right Precision Optical Cube

Choosing the appropriate precision optical cube involves considering several key factors to ensure it meets the specific needs of your application.

4.1 Optical Specifications

Evaluate the optical specifications of the cube, including its wavelength range, beam splitting ratio, and polarization characteristics. Ensure that the cube’s specifications align with the requirements of your optical system or experiment.

4.2 Material and Quality

Select a cube made from high-quality optical materials to ensure minimal distortion and maximum performance. The clarity and precision of the optical surfaces are critical for achieving accurate light manipulation.

4.3 Size and Design

Consider the size and design of the optical cube to ensure it fits within your optical setup. Precision alignment and integration are essential for maintaining the cube’s performance and accuracy in your system.

Read also: Smart Home Renovation: Integrating Technology for Modern Living

5. Maintenance and Care of Precision Optical Cubes

Proper maintenance and care are essential for preserving the performance and longevity of precision optical cubes.

5.1 Regular Cleaning

Clean optical cubes regularly to remove dust and contaminants that can affect their performance. Use specialized lens cleaning solutions and soft, lint-free cloths to avoid scratching or damaging the optical surfaces.

5.2 Storage Conditions

Store precision optical cubes in a clean, dry environment to prevent damage and contamination. Use protective cases or covers to shield the cubes from dust, scratches, and other potential hazards.

5.3 Inspection and Calibration

Periodically inspect optical cubes for signs of wear, damage, or misalignment. Ensure that they are calibrated correctly to maintain their performance and accuracy. Address any issues promptly to avoid impacting your optical system’s functionality.

6. Innovations and Future Trends

The field of precision optical cubes is continually evolving, with new advancements enhancing their capabilities and applications.

6.1 Advanced Coatings

Researchers are developing advanced coatings for precision optical cubes that offer improved performance and durability. These coatings enhance light manipulation and resistance to environmental factors.

6.2 Miniaturization and Integration

There is a trend towards miniaturizing precision optical cubes to fit into compact and portable devices. Integration with digital technologies and micro-optics is expanding the range of applications and enabling new functionalities.

6.3 Smart Optical Cubes

Innovations in smart optical technologies are leading to the development of precision optical cubes with integrated sensors and control systems. These smart cubes offer enhanced functionality and adaptability for advanced optical applications.

7. Conclusion

Precision optical cubes are vital components in a wide range of optical systems, offering precise control and manipulation of light. Understanding their types, applications, and maintenance requirements is crucial for leveraging their full potential in various fields. By staying informed about the latest advancements and trends, you can ensure that your optical systems remain at the forefront of technology and performance. Whether used in scientific research, telecommunications, imaging, or other applications, precision optical cubes continue to play a pivotal role in advancing optical technologies and achieving exceptional results.